Relong Eletric Submersible sand pump

Single-use or matched with Relong submersible slurry pump dredger(as picture) used for conveying slurry containing abrasive solid particles in the chemical industry, mining, thermoelectricity, metallurgy, pharmaceutical, bridge and pile foundation engineering, coal, environmental protection, and other industries. Such as iron and steel factory pumping iron sheet, sediment cleaning factory sediment tank, gold panning, concentrator pulp, and sand transport, metallurgy concentrator pulp transport, thermal power plant hydraulic ash removal, coal washing plant slurry and heavy medium transport, dredging river, river pumping sand dredging, pile foundation engineering.

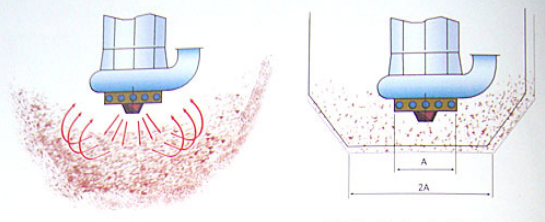

In addition to the main impeller, the bottom is also equipped with a stirring impeller, a motor shaft to drive the pump impeller, a stirring impeller high-speed rotation, and the energy transfer to the slurry medium, so that the sediment, slag slurry, and another uniform mixing, extraction so that the pump in the absence of auxiliary devices to achieve a high concentration of transport.

In addition, for the special working conditions where the sediment is stiff or the sediment layer is hard, only the impeller of the pump and the self-priming can not be completed, the two sides and multilateral stirrer (reamer) can be added to loosen the stiff sediment, improve the extraction concentration, and achieve automatic reaming. Also can prevent the bulk of solid material will block the pump so that the solid and liquid are fully mixed so that it is easier to handle.

Dredging Area(Left is without agitor, right is with agitors)

1. It is mainly composed of a motor, pump shell, impeller, guard plate, pump shaft, bearing seals, etc.

2. The material of the pump shell, impeller, and guard plate is made of high chromium alloy wear-resisting material, which has strong wear-resisting, corrosion-resisting, and sand-discharging ability and can pass through large solid particles.

3. The whole machine is dry pump type, the motor adopts oil chamber sealing mode, equipped with three sets of hard alloy mechanical seal, which can effectively prevent high-pressure water and impurities into the motor cavity.

4. In addition to the main impeller, there is also a stirring impeller, which can precipitate the sludge on the bottom of the water into turbulence after extraction.

5. The impeller is in direct contact with the deposition surface, and the concentration is controlled by diving depth. In addition, the auxiliary reamer can be added to increase the concentration of medium extraction because of the high hardness and compaction of medium precipitation.

6. Not limited by suction range, high slag absorption efficiency, and more thorough silt removal.

7. The equipment works directly underwater, without noise and vibration, making the site cleaner.

1. Normally 380V / 50Hz, three-phase AC power supply. Also can be customized 50Hz or 60Hz / 230V, 415V, 660V, 1140V three-phase AC power supply, distribution transformer capacity is 2-3 times the rated capacity of the motor. (Indicate power supply condition when ordering)

2. The working position in the medium is vertical upper suspension positioning, which can also be coupled with installation, the working state is continuous.

3. Diving depth of the unit: no more than 50m, the minimum diving depth shall be subject to the submerged motor.

4. Maximum concentration of solid particles in the medium: ash slag is 45%, slag is 60%.

5. Medium temperature shall not exceed 60℃, R type (high-temperature resistance) shall not exceed 140℃, without flammable and explosive gases.